Your Cart is Empty

Recent Articles

- Efficiency Meets Innovation: SketchUp 2024 Unveiled

- Maxon One Spring 2024 Release Packs Particle Power, Toon Shading, and More

- TurboCAD 2024 Unveiled by IMSI Design: Discover the New Features and Enhancements

- Exploring the Latest InfraWorks 2025 Updates

- Introducing the Latest Innovations in Autodesk's ReCap Pro 2025

- Discover the Latest Enhancements in Civil 3D 2025

- Exploring the Newest Features and Enhancements in Revit 2025

- Explore the Latest Features in Vantage 2.3 Update

- Explore the Latest AutoCAD 2025 Enhancements: Activity Insight, Smart Blocks, and Apple Silicon Support

- Unveiling Enscape 4.0: Revolutionizing Design with Unified Experience for macOS and Windows Users

NOVEDGE Blog

Efficiency Meets Innovation: SketchUp 2024 Unveiled

by Barbara D'Aloisio April 11, 2024 0 min read

Read More

Maxon One Spring 2024 Release Packs Particle Power, Toon Shading, and More

by Barbara D'Aloisio April 10, 2024 0 min read

Read More

TurboCAD 2024 Unveiled by IMSI Design: Discover the New Features and Enhancements

by NOVEDGE April 10, 2024 0 min read

Read More

Introducing the Latest Innovations in Autodesk's ReCap Pro 2025

by NOVEDGE April 05, 2024 0 min read

Read More

Exploring the Newest Features and Enhancements in Revit 2025

by NOVEDGE April 03, 2024 0 min read

Read More

Explore the Latest AutoCAD 2025 Enhancements: Activity Insight, Smart Blocks, and Apple Silicon Support

by NOVEDGE March 29, 2024 0 min read

Read More

Unveiling Enscape 4.0: Revolutionizing Design with Unified Experience for macOS and Windows Users

by NOVEDGE March 28, 2024 0 min read

Read More

New PTC Mathcad Prime 10: Empowering Engineers with Advanced Engineering Calculations

by NOVEDGE March 22, 2024 0 min read

Read More

Unveiling BricsCAD V24.2: Explore the Latest Features and Enhancements

by NOVEDGE March 19, 2024 0 min read

Read More

Unveiling Mocha Pro 2024: SynthEyes 3D Tracking Revolutionizes VFX Workflow with New Camera Solve Module

by NOVEDGE March 18, 2024 0 min read

Read More

MecSoft Unveils RhinoCAM and VisualCAD/CAM 2024: Elevate Your Design and Manufacturing with New Features and Enhancements

by NOVEDGE March 15, 2024 0 min read

Read More

What's New in KeyShot 2024.1 : Ultra-Sharp Visuals and Enhanced Workflow Efficiency

by NOVEDGE March 12, 2024 0 min read

Read More

Mastering Stone Creation and Setting with RhinoArtisan: A Revolutionary Plugin for Rhino

by NOVEDGE March 08, 2024 0 min read

Read More

Introducing form•Z Core: The Evolution of form•Z Jr with Enhanced Features and v10 Updates

by NOVEDGE March 08, 2024 0 min read

Read More

Exploring the Exciting New Features of 3ds Max 2024.2 Update

by NOVEDGE March 03, 2024 0 min read

Read More

Unveiling V-Ray 6 Update 2 for Maya: Revolutionizing Creative Connectivity and Rendering Efficiency

by NOVEDGE February 15, 2024 0 min read

Read More

Unlock Next-Level Creative Collaboration with V-Ray 6 for Houdini Update 2

by NOVEDGE February 15, 2024 0 min read

Read More

CivilCAD 11 : Pioneering Innovation in Civil Engineering

by NOVEDGE February 07, 2024 0 min read

Read More

Last Chance to Save 33% on Rhino 8 Commercial Upgrades: Ends February 27, 2024!

by NOVEDGE February 07, 2024 0 min read

Read More

Explore the New Features of VisualARQ 3 Beta: Now Available for Rhino 8 Users!

by NOVEDGE February 02, 2024 0 min read

Read More

Exploring the New Frontier of Jewelry Design with RhinoArtisan 5.4: Features That Personalize Your Creative Process

by NOVEDGE February 01, 2024 0 min read

Read More

Maxon Unveils Red Giant 2024 Update with New Bokeh Tools, Enhanced Color Management, and Cloud Capsule Support

by NOVEDGE January 19, 2024 0 min read

Read More

Exploring the Autodesk Civil 3D 2024.3 Update: What's New and Enhanced?

by NOVEDGE January 04, 2024 0 min read

Read More

Evaluating 3D Architectural Rendering Options: Should You Go In-House, Learn Yourself, or Outsource?

by NOVEDGE December 15, 2023 0 min read

Companies face a crucial decision when it comes to producing these renderings: opt for an in-house team, invest time in self-learning, or turn to outsourcing services?

Read More

Expedite Your Creation Process With RhinoArtisan 5.2

by NOVEDGE December 12, 2023 0 min read

RhinoArtisan 5.2, is compatible with Rhino 6, 7, and 8 and introduces revolutionary features that will boost your creativity and efficiency.

Read More

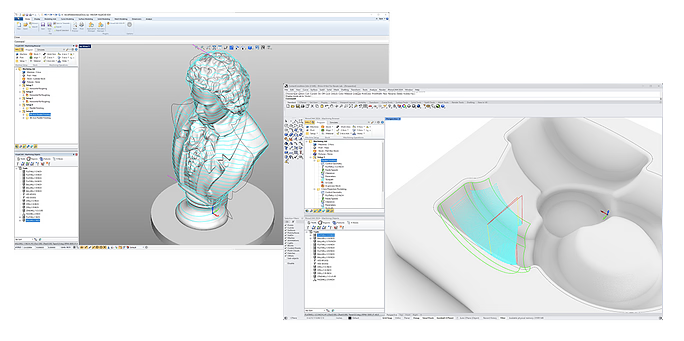

QUICKSURFACE 2024: The Ultimate Reverse-Engineering Software for Parametric Design

by NOVEDGE December 11, 2023 0 min read

Read More

Explore and Present V-Ray Scenes in Real-Time with Chaos Vantage 2: The Revolutionary Visualization Tool for Designers and VFX Artists

by NOVEDGE December 08, 2023 0 min read

Read More

Exploring the New Features of V-Ray Update 2: Improved User Experience and Accelerated Workflows

by NOVEDGE December 07, 2023 0 min read

Read More

Exploring the New Features of V-Ray 6 Update 2 for Cinema 4D: A Game-Changer for Collaboration and Rendering

by NOVEDGE December 07, 2023 0 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …