Your Cart is Empty

Recent Articles

- Efficiency Meets Innovation: SketchUp 2024 Unveiled

- Maxon One Spring 2024 Release Packs Particle Power, Toon Shading, and More

- TurboCAD 2024 Unveiled by IMSI Design: Discover the New Features and Enhancements

- Exploring the Latest InfraWorks 2025 Updates

- Introducing the Latest Innovations in Autodesk's ReCap Pro 2025

- Discover the Latest Enhancements in Civil 3D 2025

- Exploring the Newest Features and Enhancements in Revit 2025

- Explore the Latest Features in Vantage 2.3 Update

- Explore the Latest AutoCAD 2025 Enhancements: Activity Insight, Smart Blocks, and Apple Silicon Support

- Unveiling Enscape 4.0: Revolutionizing Design with Unified Experience for macOS and Windows Users

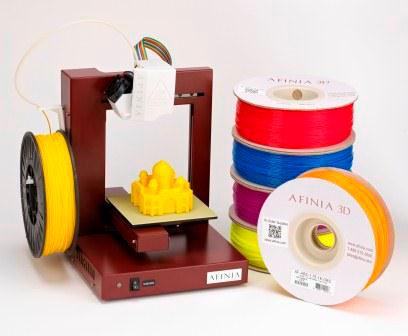

Interview with the Afinia Team: Aaron Pratt

January 15, 2013 5 min read

Novedge: Tell us about yourself and what you do

Aaron Pratt: I’m Afinia’s Vice President of Marketing. In my personal life, I’m a husband and a father of seven, and I love playing the piano and reading.

Afinia is the new business division of Microboards Technology, which has been developing robotics and printers in the CD/DVD industry for twenty years. In the new business division, we are experimenting with all kinds of printing-related robotic technology. 3D printing is the most prominent of them. But we're also playing with very high speed label printing, and with some devices for the medical industry as well. It's a fun place to be. And we know 3d printers especially well because we use them in our own design and prototyping every day.

Novedge:What inspires you?

Aaron Pratt:I’m inspired by ideas. I spend a lot of time reading about ideas. I like reading about foreign policy and economics, about communications and language, and about art and science. To me it is important not only to test ideas and see if they work, but to choose to see the world through models and ideas that bring about good – good art, good relationships, good feelings. I see 3D Printing as a tangible manifestation of that – enabling creation, transferring ideas to the physical world – making us all designers and artists.

One of the best books I read last year was Seth Godin’s Linchpin. It talked about making good art and giving it away. As an artist, I was inspired by the idea of seeing my work as art and a gift to the world, and seeing income and career as a residual effect instead of the purpose.

Not long after I read Godin’s book, I had a visit at my office from a 3d Printing Enthusiast named Peter Leppik. He’s an endearing person, very smart and enjoyable to talk to. He showed me a set of toy gears that clip together he’d designed for his nephew for his birthday. You can see them (and download the files) here http://www.thingiverse.com/thing:30981. What a great way to give something of yourself. Maybe Sam will grow out of the gears someday, but what a great expression of love to design and print something like that.

We also have another user who volunteers his time designing devices for helping disabled children. Because of how children grow and change, assistance devices require much more customization. This guy is a talented mechanical engineer and designer. Before he bought a printer I invited him to send me a design he was trying to wrap up and printed it for him. Even though I had put many hours in at one of our printers I was awed at how beautiful this part was when it came off the printer. I remember we did it in yellow at his request, and it was the first time I'd used our yellow filament, and it worked absolutely perfectly, the first time, and was something that I was really proud to send him.

Novedge:What are you most proud of at Afinia? What is the biggest challenge you overcame?

Aaron Pratt:I’m proudest of our out-of-box experience. If that sounds like a product pitch, well, it is, but it really is our highest accomplishment. We were what you would call a “late market entrant”. We came in to the market because we know how to commercialize a product, and we saw a lot of companies that don’t know how to do that. Things that are painful to users are not obvious to companies that are experts in the technology. We worked with a manufacturer and said “Let’s fix this. Mount the LED here. Make sure it comes out of the box in one piece. Fix the little tiny bugs. Rewrite the manual.” We went around the country meeting with users. We toured supplier facilities in China. We’ve tested dozens of filament suppliers. We changed everything, right down to the packaging itself, to make sure that users would want to tell their friends how easy we were to use, especially compared to whatever tinker toy they had pulled their hair out trying to assemble last. You can see a very detailed description of the out-of-box experience as my counterpart, John Westrum, steps you through it here:

In it, he describes every step and every accessory in the box – in less than 30 minutes. When I’m setting one up at a show, it takes me under five minutes to have it set up and recognized by the PC.

Getting the product just right is what will allow us to recreate Peter’s experience tens of thousands of times. One of our users designs customized parts for assistance devices for disabled children. I just talked to another guy who builds airships who wants one for his shop and to introduce his son to design and prototyping. That’s just a small handful of the many stories we’ve been involved in.

Novedge: What is special about Afinia's 3D printers? What software is best used when designing an object to be 3D printed with them?

Aaron Pratt:What's special about our printers is the experience. The speeds and feeds of the various devices on the market is all about the same. It’s what happens around the machine that makes us awesome. Try calling our tech support – if they don’t answer immediately, they will within a business day. (Seriously – try it – 952.279.2643). Or e-mail us. Or Twitter us. Or Facebook us. We’re very responsive.

The software is strong too – again, all part of having a flawless user experience. Our software is one step: open the STL and hit print. You can do some manipulation, of course – scaling it, placing it where you want it to print, rotating it, adjusting support material and so on. But there’s no pre-processing, exporting G-Code, and so on. That’s all done in the background. And once the file has been sent to the printer, you can unplug the USB cable and walk away.

So far we’ve had great experience with all the design software that can output STLs. In-house, we’re a Solidworks-centric company. But lots of our designers use the other major packages. (And some of the obscure ones, too.)

Novedge: What innovations do you see in your field now or in the future?

Aaron Pratt:The big ones that everyone is talking about are print envelope (larger part sizes), speed, and materials. I see all three as part of the near future. I think the first one you can expect to see from us is a larger print envelope. We also recently announced an enhancement in resolution (from .20 mm to .15mm), and I anticipate there will be more of that in the future. The one I am most excited about is materials. I can’t promise anything yet, but I am really looking forward to being able to make some announcements about different plastics and beyond.

All images courtesy of Afinia.

Also in NOVEDGE Blog

Maxon One Spring 2024 Release Packs Particle Power, Toon Shading, and More

April 10, 2024 4 min read

Read More

TurboCAD 2024 Unveiled by IMSI Design: Discover the New Features and Enhancements

April 10, 2024 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …