Your Cart is Empty

Recent Articles

- Efficiency Meets Innovation: SketchUp 2024 Unveiled

- Maxon One Spring 2024 Release Packs Particle Power, Toon Shading, and More

- TurboCAD 2024 Unveiled by IMSI Design: Discover the New Features and Enhancements

- Exploring the Latest InfraWorks 2025 Updates

- Introducing the Latest Innovations in Autodesk's ReCap Pro 2025

- Discover the Latest Enhancements in Civil 3D 2025

- Exploring the Newest Features and Enhancements in Revit 2025

- Explore the Latest Features in Vantage 2.3 Update

- Explore the Latest AutoCAD 2025 Enhancements: Activity Insight, Smart Blocks, and Apple Silicon Support

- Unveiling Enscape 4.0: Revolutionizing Design with Unified Experience for macOS and Windows Users

The Edge: Kreysler & Associates – The Leap in Digital Fabrication

January 13, 2015 5 min read

Novedge: Tell us a bit about Kreysler & Associates and what the Company does.  Kreysler: Kreysler is a custom fabrication company specializing in composites and digital fabrication. Our focus is on Architectural projects, especially facades and large-scale artwork. We've been in business since 1982 and have about 35 employees. Our production staff is highly skilled and experienced in composite fabrication. One of our greater strengths is in the way we merge our knowledge of traditional "hand-made" techniques with the latest technology, often building our own equipment and custom machine protocols to suit a project. A deep appreciation for craftsmanship as it applies to both the digital and the hand is the cornerstone of our success building high quality, custom products.

Kreysler: Kreysler is a custom fabrication company specializing in composites and digital fabrication. Our focus is on Architectural projects, especially facades and large-scale artwork. We've been in business since 1982 and have about 35 employees. Our production staff is highly skilled and experienced in composite fabrication. One of our greater strengths is in the way we merge our knowledge of traditional "hand-made" techniques with the latest technology, often building our own equipment and custom machine protocols to suit a project. A deep appreciation for craftsmanship as it applies to both the digital and the hand is the cornerstone of our success building high quality, custom products.

Novedge: The list of projects you have worked on is so eclectic , can you talk about some of your favorite ones ?

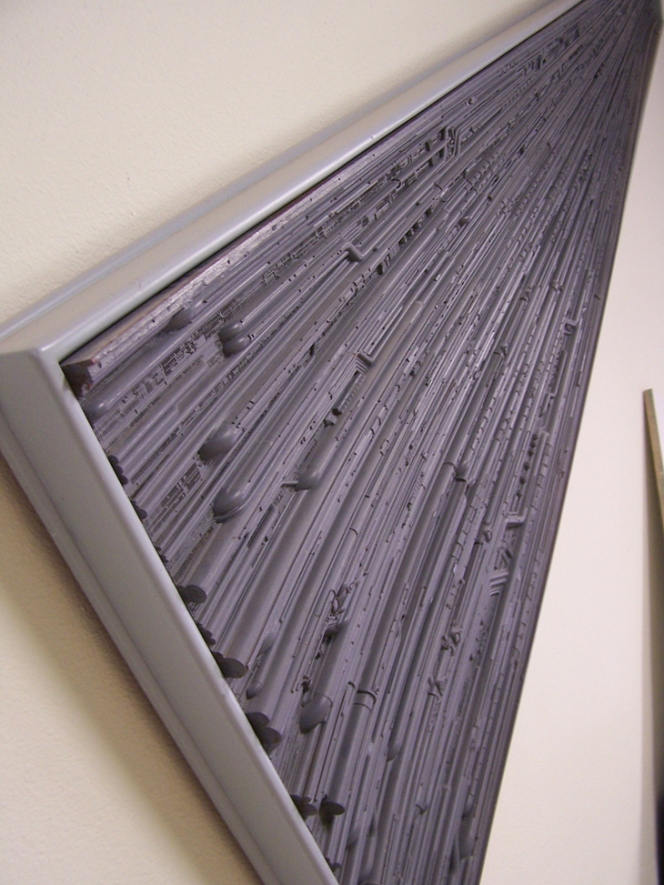

Kreysler: The composite facade of the expansion to the San Francisco Museum of Modern Art is our latest and greatest accomplishment. It has been a success so far and has given us an opportunity to apply practically every aspect of our skills and resources to a high profile project right in our own back yard. Leading up to this project, our in-house R&D pertaining to fire resistant composites has opened the door to more widespread use of these materials in the future. The whole process has relied heavily on our facility with software – in our case Rhino– for early conversations with the designers all the way through construction coordination, in-house fabrication, production tracking, and quality control. One of my favorite victories on this project was in the development of our own toolpath generator and post processor with Rhino/Grasshopper for our CNC hotwire cutter. It's a low-visibility step in the process but a huge time saver and a good example of the way we adapt the tools we have to the task at hand.  SF MOMA expansion, facade.

SF MOMA expansion, facade.

"Leap" , a 56' long aluminum rabbit in the Sacramento International Airport, was a great showcase of digital fabrication. It's made of about 3500 individual, unique pieces of CNC cut aluminum all welded together and suspended from 7 steel cables. The entire thing was essentially completely assembled digitally using Rhino, relying heavily on it's built-in scripting language. Once all the details were figured out in the model, right down to material thicknesses and detailed part labels, it was all sent out to be CNC cut at a boat-building shop up in Seattle with a machine particularly well adapted to cutting out aluminum sheets. Once we got the parts, with the 3D model in hand right next to the guy assembling and welding the whole thing went together in a snap.  Leap, Sacramento International Airport.

Leap, Sacramento International Airport.

Novedge: What should we expect in the future of composite materials?

Kreysler: Our specialty is in the architectural applications of composites. As we see it, there are huge opportunities for composites in the construction industry that have yet to be taken advantage of. Digital CAD tools are enabling architects to develop designs that are extremely geometrically complex and often lend themselves to strong, lightweight materials like fiberglass. Construction law and building codes have some catching up to do with respect to digital methods of construction and modern materials and often hinder efficient solutions that might involve composites but progress is being made. For example, the fire resistance breakthroughs on the SF MoMA, allowing plastics to be used on facades, are a big step that I think will open the door a little wider. Industry associations are currently working on taking this to the next step to allow their use more extensively, even structurally – that's what we should see more happening in the near future.

Novedge: What software do you use and why?

Kreysler: Rhinois like our "digital pocket knife". It's intuitive, inexpensive, adaptable, and has a huge community of users for support and developing custom tools. Nearly every project we do sees Rhino at one point or another. We have a couple of 3D scanners and we often deal with scan data in the form of large meshes – we've bounced around to a few different programs for this in the past including Geomagic and Meshlab. For the most part this amounts to mesh cleanup, hole filling, and cutting models into pieces that are digestible by our machines. PowerMILL is what we use for programming our 5-axis milling machines and recently-acquired Kuka robot. Eureka for toolpath verification. We have Revitsince we're often involved in construction projects involving BIM coordination, although since we're fabrication-focused we tend not to rely on that for tasks outside of coordination. We're constantly exploring new software as it appears and often will try something in Beta on a production project. Lately we've been intrigued by some of the latest Autodesk projects such as Meshmixer, the 123D tools, and Memento.

Novedge: What's the effort towards sustainability in the firm's practice?Sustainability is a popular and important issue facing designers, builders and building owners. Unfortunately, it is also complex. Since 2009, Kreysler & Associates has worked with Professor Michael Lepech PhD and his graduate students at Stanford University’s School of Environmental Engineering to compare FRP(Fiber Reinforced Polymer) systems to other materials in given situations. Both ourselves and the students have often been surprised at the results. Intuition suggests that FRP would not be a very “green” solution since it comes from petroleum. Surprisingly however this assumption is nearly always wrong. You can check out the "Life Cycle Assessments" on three of Kreysler's projects here.

Novedge: You have worked for the Film Industry; what are some of the blockbuster movie sets you have helped build?

Kreysler: Kreysler was originally located in Petaluma near the Lucas Ranch and they had the opportunity to build some things for those sets including the sails on Jabba the Hut's barge, some bunkers on the moon of Endor, and the reactor room in the center of the Death Star.

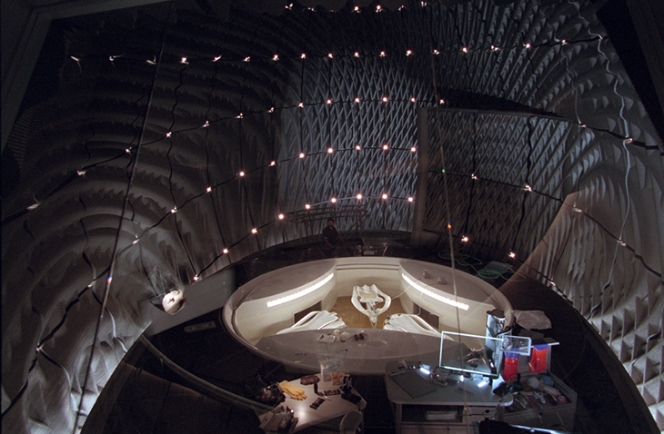

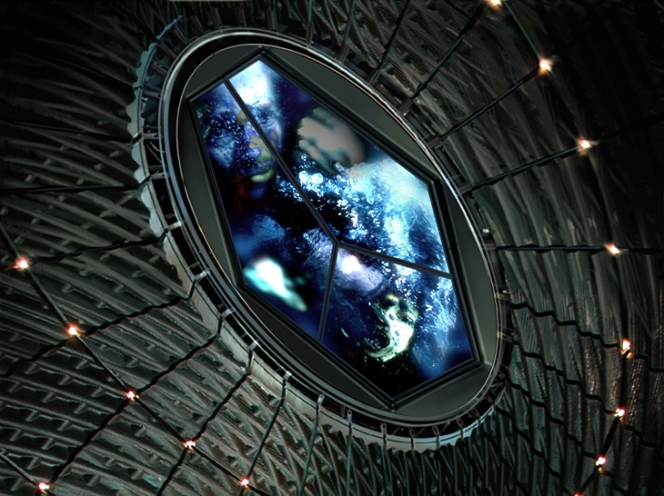

Kreysler made some CNC-machined panels lining the inside of the pre-cog chamber in Minority Report. Perhaps most notable because it was K&A's first all-digital project with no physical shop drawings or other artifacts other than the product itself. As the story goes, the only piece of paper was the purchase order.

Minority Report's pre-cog chamber.

Minority Report's pre-cog chamber.

Novedge: Is there a Country at the Avant Guarde in terms of Composite Material Innovation? Which one?

Kreysler: This is a tricky one. Innovation in composites seems to be happening everywhere and in many different industries including aerospace, energy, transportation, marine, and construction to name a few. There is a great deal of interesting innovation happening here in the US. And there are many interesting projects in Europe and Asia and I'd say there's a much greater deal of Composite Material use in those regions – at least architecturally. A lot of advancement happens – especially from an engineering standpoint – as they develop the boats they build for the America's Cup which we just recently witnessed in the SF Bay Area. Making windmill blades longer drives innovation because the bigger the blade, the more energy they can squeeze out of it. Nasa and some of the private companies like SpaceXrely on composites for rocket construction. I hear there's a lot of research on recycling composites in europe, especially carbon fiber. So I don't know if there's a particular country leading the way since there are so many avenues for innovation – depends on where you look.

Kreyselr and Associates is one of Novedge's most inspiring customers. For more examples of Composites and Architecture check out the Blog they sponsor.

And don't forget to follow us on Twitter and Facebook for more software news and inspiring interviews.

Also in NOVEDGE Blog

Maxon One Spring 2024 Release Packs Particle Power, Toon Shading, and More

April 10, 2024 4 min read

Read More

TurboCAD 2024 Unveiled by IMSI Design: Discover the New Features and Enhancements

April 10, 2024 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …